BECAUSE A STUPID FIRE ALARM IS GOING OFF, I COULDN’T PROOF READ THIS EVEN IF I WANTED TO.

WHICH I DON’T. ANYWAY…

A while back I made the offhand comment that “Paypal would fly you to space”, and what I was of course talking about there was that PayPal founder Elon Musk took the megamoney he made there and went on to found SpaceX. One of SpaceX’s vehicles is a rocket called the Falcon 9, which advertises a LEO lift capacity of 23,050 pounds (a hair over 10,000kg, or a little less than half the Space Shuttle, or a less than a tenth the size of America’s retired massive Saturn V rocket) and is their largest lift vehicle. More importantly perhaps, it is as I write this the most economical and competitive launch system (much to the chagrin of China’s Long March rockets which had hoped to compete). But what is that “cheap” price? The cost per full launch of the Falcon 9 is a minimum of $54 million, or over $5000 per kilogram to LEO. Frankly I am not impressed, but lets look a little closer at those costs.

First of all, the Falcon 9 is not currently reusable, and so can only be used once. SpaceX is naturally working to make the Falcon 9 reusable in the future because it should reduce launch costs. Elon Musk has said that with enough launches the cost per launch could be reduced by a factor of one thousand — which would be remarkable. Of course, he still has to pay off the $300 million in development costs on the Falcon 9, to say nothing of the costs of developing what sounds like a very expensive recovery procedure (the rocket uses a single engine to return to the launch site and lands bottom-down vertically after upper stage separation). I hope that happens, but it’s a difficult problem to solve, and until then, the cost stays at $54 million plus per launch. I was very interested to read that the kerosene and oxygen that the Falcon 9 uses is about $200,000 per launch. So only 0.3% of the cost is fuel — basically nothing. I find that shocking. But I suppose it’s not that different from a car — you spend $20,000 for the vehicle and then a few dollars to drive it a hundred miles. If you had to throw the car away at the end of every trip, either driving would cost a fortune. You’d have to either figure out a way how to reuse your car, or figure out how to build a car at a fraction of the cost.

It’s funny because in SpaceX’s brochure they describe their philosophy as “simplicity, reliability and low cost”, but even they admit that their production delays were caused by the enormous complexity of the project. Those of you (anyone?) who actually slog through these entries know that the 1962 Sea Dragon rocket which had launch costs at the low end of $59 per kilogram or $600 at the high end. Yet the best we can come up with today, sixty years later, is over $5000 a kilogram. Parts of the Sea Dragon design is similar to the Falcon 9 in that the first stage uses the same fuel mixture — kerosene and oxygene. However, the Falcon 9 uses a 3×3 cluster of nine SpaceX Merlin engines of 125,000 pounds thrust, whereas the Sea Dragon uses a ridiculously scaled up single massive 80,000,000 pound thrust engine. They did this not just for “true” simplicity, but also because from a cost point of view, it’s not significantly more expensive to build a big rocket engine than a small rocket engine — the raw materials are not the main cost. The entire Sea Dragon rocket is essentially just a big metal tube, built out of inexpensive sheet metal. Every cost is brought as low as possible, thus the term “Big Dumb Rocket” (which I’ve linked before).

As I mentioned, development work on the Falcon 9 was $300 million. The development cost of a similar engine, this one designed for 250,000 pounds of thrust (twice as big as SpaceX’s Merlin engine), including all testing was $60,000 (in 1966 dollars). Half of that was the cost of building the engine. The best part of the story, which I have to share, is how the engine was built:

“TRW farmed-out the fabrication of the engine and its supporting structure, less the injector that they fabricated themselves, to a “job-shop” commercial steel fabricator located near their facility . The contract price was $8000. Two TRW executives visited the facility to observe the fabrication process. They found only one individual working on the hardware, and when queried, he did not know nor care that he was building an aerospace rocket engine.”

The fuel tanks were fabricated not by some ultra-high-tech space contractor, like they are today, but by a commercial tank builder at a cost of a few dollars per pound of tank weight (a number which would be lower if done in-house of course).

It really drives me nuts. Low cost rocketry is very do-able. We’ve known how to do it since the sixties. And when I say “known how”, I do not mean theoretically like with Project Orion’s nuclear ships. I mean “known how” as in we built the technology and tested it. But as with all things that involved contracts between megacorporations and megagovernments, would they rather sell a rocket for $54 million, or would they rather sell a rocket for $250,000? I know we all know the answer. It really drives me nuts. I so badly want to see cities in space and when I look up at the moon I want it to look like the Earth at night, dotted with the lights of a thousand cities. Am I asking too much of humanity? It just seems to close, so possible, I feel like I can almost touch it.

Maybe my photoshopping is not so impressive but here is what the Earth looks like from the space station. After all, in my fantasy world if you don’t like the way the moon looks at night you can always just look at the Earth from the moon instead. I sure would like to live long enough to help make this a reality.

Everything I’ve mentioned so far in this entry is “down-to-earth” (pardon the inappropriate phrase) technology, but I did want to mention one other issue that’s a bit farther into the theoretical realm. But not so far that we shouldn’t have done it decades ago.

According to NASA, by the time the Shuttle has hit 1,000 mph (which it does in about a minute), it has consumed a million and a half pounds of fuel, or about a third of what it carries. After two minutes, the shuttle is up to 3,000 mph and the solid rocket boosters separate (each of which have over a million pounds of powdered aluminum and ammonium percolate). NASA has floated designs for maglev “rocket sled tracks” capable of accellerating a 500+ ton lift vehicle up to at least Mach 2, using — and this is very important — only currently existing technology. I’m not even talking about more abitious systems like the Star Tram or a Lofstrom loop which are capable of sled-launching cargo (including humans) into orbit using only the acceleration on the track. What I’m talking about is a simple launch assist system that we could build any day we will it. The cost of constructing such a launcher was estimated to be less than $100 million, or about a quarter of the $450 million average it took for a single Space Shuttle launch. I can’t wrap my head around why this wasn’t done. It really feels like a willful conspiracy to keep the costs as high as possible.

Not that willful conspiracies by the wealthy to defraud taxpayers is anything new. In fact, the historical record is such that I’d say that Occam’s razor pretty much demands it.

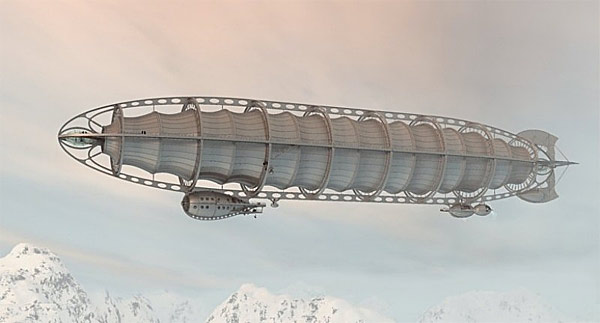

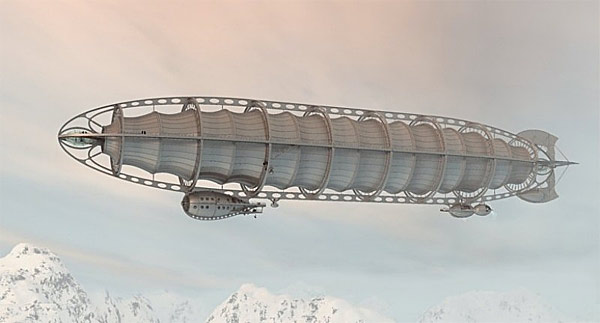

Finally, you may remember years ago I had a brief interest in the idea of lighter than air yachts, the notion of building luxury airships that would sit in the same market sector as yachts do today. So instead of taking your rich friends out on the sea, you’d go for a cruise over the rain forest, silently drifting fifty feet over the tree tops in a whisper-quiet electrically propelled and computer guided floating pleasure craft. I still think it’s a good idea. But it was brought back to mind when I saw pictures from a Russian 3D artist of a “vacuum ship”:

Blimps float because what they contain — helium generally — is lighter than the ambient air (just like hot air baloons float because the warmer air is the less dense it is). But what’s lighter than helium? The smart-alleck answer is “nothing”. “Nothing” as in literally nothing, as in a vacuum. There is nothing lighter than nothing at all.So that’s what this is. The problem we have is that a vacuum means that the totality of the surrounding atmosphere is crushing the chamber, and it’s extremely difficult to find a material that is strong enough to deal with those forces while still being light enough to float in the air. That said, his design is clever (and you could optimize it by floating a tensigrity balloon inside a geodesic dome) and might actually be more doable than he thinks (in the English translation you can see that he believes no suitable material exists).

Other than that as you can see I made some casts of my teeth (using fast-setting dental alginate to make the mold) to start building some prosthetics for fun. The neat thing is I can see the chips on the sides of my molars from when I bit my tongue barbells. I hate touching the stone/plaster material though, it feels like scratching a chalkboard. Speaking of, I don’t like touching chalk either. Hurts like crazy the way it stimulates the nerves. I’m not sure if everyone feels like that or not? The fire alarm in our building has been malfunctioning so Caitlin and I have had our sleep messed up a bit this week, plus we got food poisoning it seems when we ordered a pizza. Hopefully I am feeling better by Thursday because I’m getting tattooed.

AW FUCK THE ALARM IS GOING OFF RIGHT NOW!!!!!

ARRGHH! I’M GETTING TO HATE THIS BUILDING!